Custom metal stamping is one of the key enabling techniques for the economical mass manufacturing of quality metal parts. Metal components are machine stamped sequentially using a set of dies that shape, cut, and form workpieces into several parts. These operations are performed with a precision and accuracy that only purpose-built stamping dies can provide. To meet the growing needs for custom metal stamping dies, a company that specializes in precision machining and die fabrication is always on standby. Why is precision machining so critical in custom metal stamping dies? In this post we will delve into the details of custom metal stamping dies and their role in productivity in manufacturing.

Understanding Custom Metal Stamping Dies

Metalistic stamping dies are specially crafted tools which sculpt sheet metal into intricate parts through pressing. They include a punch, die block, and various supporting structures that ensure accurate shaping. Precision machining companies have modern manufacturing systems that guarantee stamping dies are made with exact tolerances so that every stamped part is correctly designed. These dies are composed of metallurgy, stress distribution, and mechanical engineering to maximize their efficiency and durability.

The primary benefit of custom metalastic stamping dies is the ability to fabricate thousands of identical components in a limited timeframe. Unlike traditional machining processes, stamping enables sophisticated geometries to be created in one press cycle, saving time and money. To reduce maintenance and wear requirements, engineers use advanced materials and coatings to increase the lifespan of stamping dies. Custom stamping dies allow any industry, be it automotive, aerospace, or consumer electronics to automate their manufacturing processes without losing consistency, repeatability, or scalability.

The Contribution of Precision Machining in Die Production

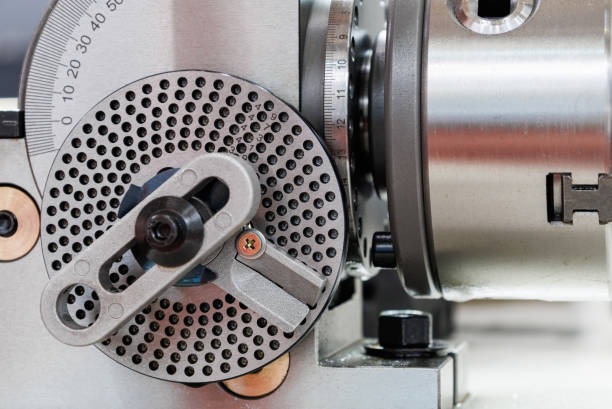

The utmost importance of precision machining lies in the manufacture of high chamfering stamping dies. A precision machining company uses modern production methods, including CNC milling, EDM (Electrical Discharge Machining), and grinding to make dies to micrometer precision. This precision is critical to allow the die to form metal components consistently without any variation.

In order to create a high-quality stamped die, engineers start by creating a digital model with CAD (Computer Aided Design) software. The model goes through several simulations for stress distribution and wear testing. After passing these tests, die components are produced with ultra precision machining to outstanding levels of measurement accuracy. This level of engineering always guarantees the right alignment of components in the stamping dies to enable optimum results. As a result, defects are minimized, and overall output efficiency is maximized.

In addition to initial fabrication, precision machining plays an important role in die maintenance and repair. With time, die surfaces wear down with each press of metal sheets. Through CNC grinding and re-machining, manufacturers can restore die to its intended specification which increases its life and consistency of production. As technology progresses, new innovations such as predictive maintenance and automated quality control are improving the effectiveness of precision machining. This guarantees that the dies will be maintained throughout their working life.

The Benefits of Custom Metal Stamping for Mass Production

Custom methods of stamping metal are especially advantageous for mass production. Efficient and cost effective approaches are needed to satisfy high-volume production. Precise engineered dies for custom stamping outperform other manufacturing approaches like laser cutting and traditional machining. Stamping machines are capable of producing thousands of parts in an hour which is ideal for industries with high demand.

Moreover, custom metal stamping accuracy lowers the amount of materials wasted. Unlike machining processes that cut away materials and leave unsightly pieces of scrap behind, stamping utilizes material efficiently by cleanly cutting and forming each part. Reduction in expenses is accompanied by the positive impact on eco-friendly Manufacturing processes because of the lowered waste. A precision machining company makes sure that every die is designed to be as distortive to material as possible, increasing yield and decreasing the need for secondary processes.

In addition, a notable benefit is repeatability. Because stamping dies are made specifically for certain parts, they’re able to make parts that are identical to each other and have little differences. This is important for sectors like automotive and aerospace where there are tight regulations. With the addition of automation and robotic work feeding, these systems are also able to increase efficiency; therefore, decreasing manpower and improving overall productivity.

Also, multi-stage stamping has been made more sophisticated without losing efficiency. For instance, progressive die stamping uses several shaping tools in one and does the tasks faster but with great accuracy. Each advancement in these processes creates new possibilities for mass metal fabrication and ensures that stamping plays a big part in industry production.

Materials and Coating for Stamping Dies

The materials used in stamping dies construction directly impacts their longevity and function. While die manufacturers primarily make use of hardened tool steels like D2, A2, and M2 due to their high toughness along with exceptional wear resistance, in high-stress applications, the use of carbide dies is preferred for even greater durability while stamping stainless steels and titaniums.

Surface treatments and coatings enhances dies performances, this includes nitriding, PVD (Physical Vapor Deposition) coatings, and titanium nitride (TiN) coatings, which dramatically improves the wear resistance and friction performance, resulting in die surface material adhesion being minimized while reducing maintenance times for cleaning the dies.

Furthermore, stamping dies are also designed utilizing metallurgical principles to enable these dies to withstand extreme pressures without deforming. Factors like heat treatment, microstructure refinement, and surface hardness are instrumental in ensuring these dies are durable throughout prolonged production cycles. The application of these advanced materials and coatings are economically beneficial as the cost efficiency and service life of stamping dies is raised along with the productivity rate while maintenance interruptions are decreased.

Advanced nanocoatings and self-lubricating die surfaces will lead nanotechnology to new heights. If these coatings successfully mitigate friction and heat, they might drastically increase die life and lower expenses. As other branches of science progress, so will the optimizations for stamping die materials, making them more efficient and durable to meet industry standards.

Conclusion

Custom metal stamping dies greatly increase productivity enabling manufacturers to produce complex metal parts like automotive panels and electronic enclosures with superior building speed. The precision engineering behind these components assures that the final product is always of the highest quality. A precision machining company plays a crucial part in engineering and manufacturing the dies utilizing modern manufacturing processes which ensure micrometer precision.

The combination of ultra precision machining with new materials guarantees that the dies are still usable after extensive production cycles and remain affordable. The future of metal stamping will always focus on improving effectiveness, automation, and the environmental friendly nature of the process. Whatever manner is used whether it is quality control through artificial intelligence, real-time monitoring, or hybrid manufacturing, custom metal stamping will continue to be a cornerstone of contemporary manufacturing for many years to come.

The upcoming developments in materials systems, coatings, and production methods suggest even more advancements are possible in stamping die performance. By integrating these improvements, manufacturers will be able to improve efficiency, reduce waste, and produce products of superior quality and accuracy.